EMC Software

Introduction

As part of our collaboration with the

OMAC User's Group,

we have written software which implements real-time control of

equipment such as machine tools, robots, and coordinate measuring

machines. The goal of this software development is twofold: first, to

provide complete software implementations of all OMAC modules for the

purpose of validating application programming interfaces; and second,

to provide a vehicle for the transfer of control technology to small-

and medium-sized manufacturers via the NIST

Manufacturing Extension

Partnership.

The EMC software is based on the NIST Real-time Control System (RCS)

Methodology, and is programmed using the NIST RCS Library. The

RCS Library eases the porting of controller code to a variety of Unix

and Microsoft platforms, providing a neutral application programming

interface (API) to operating system resources such as shared memory,

semaphores, and timers. The RCS Library also implements a

communication model, the Neutral

Manufacturing Language, which allows control processes to read and

write C++ data structures throughout a single homogeneous environment

or a heterogeneous networked environment.

The EMC software is written in C and C++, and has been ported to the

PC Linux, Windows NT, and Sun Solaris

operating systems. When running actual equipment, a

real-time version of Linux

is used to achieve the deterministic computation rates required (200

microseconds is typical). The software can also be run entirely in

simulation, down to simulations of the machine motors. This enables

entire factories of EMC machines to be set up and run in a computer

integrated manufacturing environment. A Windows NT simulation self-installing

archive runs the controller on simulated DC motors, with a Java

GUI.

The EMC software is available free of charge on our FTP site. Please

read the README

file before getting or installing the software.

|

This software was prepared by United States Government employees as

part of their official duties and is, therefore, a work of the

U.S. Government and not subject to copyright.

|

The EMC at Work

EMCs have been installed on many machines, both with servo motors and

stepper motors. Here is a sampling:

|

3-axis Bridgeport knee mill at Shaver Engineering. The machine uses DC

brush servo motors and encoders for motion control, and OPTO-22

compatible I/O interfaced to the PC parallel port for digital I/O to

the spindle, coolant, lube, and estop systems.

|

|

|

3-axis desktop milling machine used for prototype development. The

machine uses DC brush servo motors and encoders. Spindle control is

accomplished using the 4th motion control axis. The machine cuts wax

parts.

|

|

4-axis Kearney & Trecker horizontal machining center at General Motors

Powertrain in Pontiac, MI. This machine ran a precursor to the

full-software EMC which used a hardware motion control board.

|

|

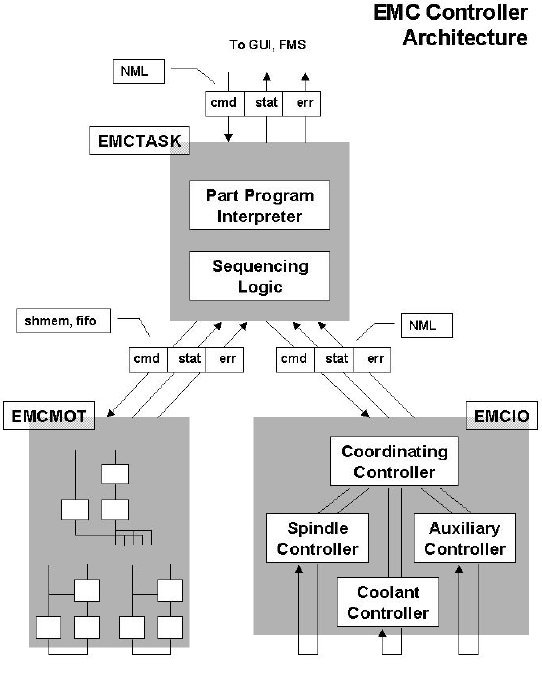

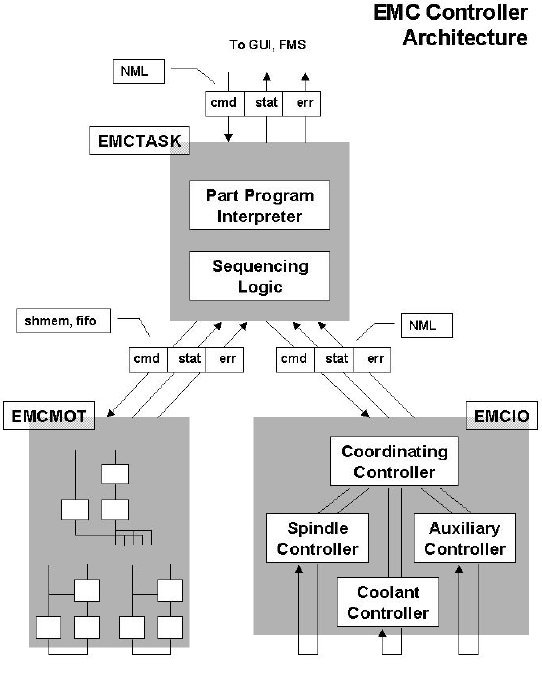

EMC Components

There are four components to the EMC software:

a motion controller (EMCMOT), a discrete I/O

controller (EMCIO), a task executor which

coordinates them (EMCTASK), and a collection

of text-based or graphical user interfaces.

Graphical User Interfaces

The EMC comes with several types of user interfaces: an interactive

command-line program emcpanel, a

character-based screen graphics program keystick, an X Windows program xemc, a Java-based GUI emcgui, and a Tcl/Tk-based GUI TkEmc.

TkEmc is most well-supported, and runs on Linux and Microsoft

Windows. The Windows version can connect to a real-time EMC running on

a Linux machine via a network connection, allowing the monitoring of

the machine from a remote location. TkEmc comes with the Linux

distribution of the EMC. Instructions for installing and configuring

the Windows version can be found in wintkemc.html.

Motion Controller EMCMOT

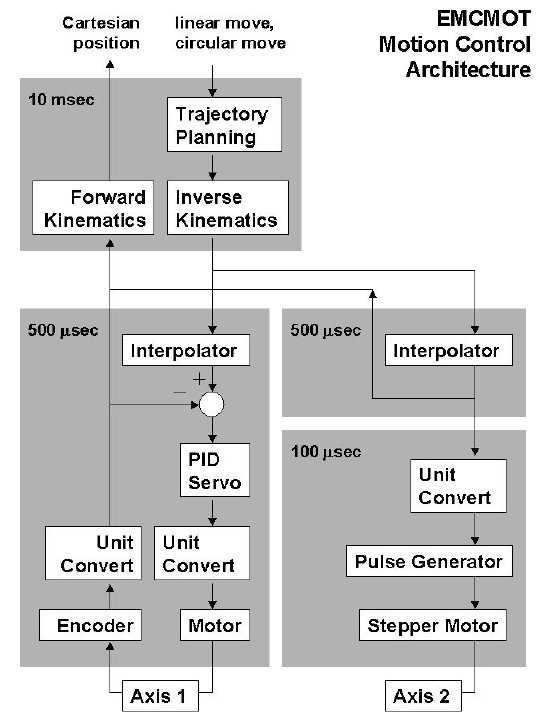

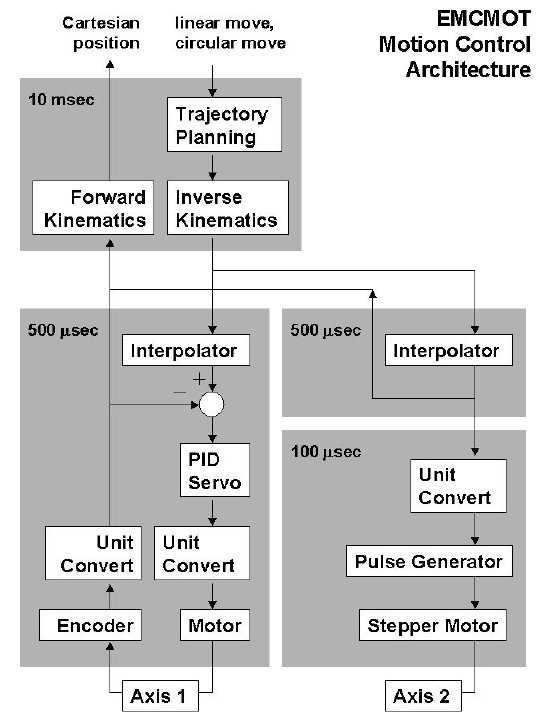

The motion controller (Figure 1) is written in C for maximum

portability to real-time operating systems. Motion control includes

sampling the position of the axes to be controlled, computing the next

point on the trajectory, interpolating between these trajectory

points, and computing an output to the motors. For servo systems, the

output is based on a PID compensation algorithm. For stepper systems,

the calculations run open-loop, and pulses are sent to the steppers

based on whether their accumulated position is more than a pulse away

from where their commanded position should be.

The motion controller includes programmable software limits,

interfaces to hardware limit and home switches, PID servo compensation

with zero, first, and second order feedforward, maximum following

error, selectable velocity and acceleration values, individual axis

jogging (continuous, incremental, absolute), queued blended moves for

linear and generalized circular motion, and programmable forward and

inverse kinematics.

The motion controller is written to be fairly generic. Initialization files (with the same syntax

as Microsoft Windows INI files) are used to configure parameters such

as number and type of axes (e.g., linear or rotary), scale factors

between feedback devices (e.g., encoder counts) and axis units (e.g.,

millimeters), servo gains, servo and trajectory planning cycle times,

and other system parameters. Complex kinematics for robots can be

coded in C according to a prescribed function

interface and linked in to replace the default 3-axis Cartesian

machine kinematics routines. A C

language application programming interface (API) between the

motion controller and the external world is provided so that specific

hardware can be integrated into the EMC without modifying any of the

core control code. Programmers must implement these API functions for

each board.

Figure 1. Motion controller software architecture. This figure shows

two axes of control, with axis 1 using a servo motor and axis 2 using

a stepper motor. For steppers, the commanded position is feed back

directly as the motor position, so the system operates open-loop. A

second task compares the output position with the accumulated pulse

count, and generates a pulse if the difference is greater than half

the pulse distance. The motion controller is a single C program,

executing cyclically. When controlling actual machines, the motion

controller requires a real-time operating

system. In our installations, we have used

RT-Linux. This gives

real-time deterministic cycle times down to about 100

microseconds. The motion controller uses either shared memory or

RT-Linux FIFOs to receive commands or send status, error, or logging

information. NML is not used directly by the motion controller since

NML requires C++ and the coding was limited to C to maximize

portability to other real-time operating systems.

Setting up Stepper Motors

Currently the EMC supports stepper motors with a 2-bit

step-and-direction interface, with bits mapped to the parallel

port. Each parallel port has 12 bits of output and 5 bits of

input. The outputs are used to drive the step and direction of each

motor. 12 bits of output mean that up to 6 stepper motors can be

controlled. The inputs can be used to detect limit or home switch

trips. 5 bits of input mean that only one axes can get full positive,

negative, and home switch inputs. The EMC mapping compromises for 3

axes of stepper motor control, with all positive limit switches being

mapped to one input, all negative limit switches being mapped to

another input, and all home switches being mapped to a third

input. Other permutations are possible, of course, and can be changed

in the software. You could also add 2 additional parallel ports (LPT2,

LPT3), and get 36 bits of output and 15 bits of input. Some parallel

ports also let you take 4 outputs and use them as inputs, for 8

outputs and 9 inputs for each parallel port. This would let you get 3

axes of control and full switch input per parallel port. See

Using the PC

parallel port for digital I/O for more information on the parallel

port.

The pinout for the EMC stepper motor interface is as follows:

Output Parallel Port

------ -------------

X direction D0, pin 2

X clock D1, pin 3

Y direction D2, pin 4

Y clock D3, pin 5

Z direction D4, pin 6

Z clock D5, pin 7

Input Parallel Port

----- -------------

X/Y/Z lim + S3, pin 15

X/Y/Z lim - S4, pin 13

X/Y/Z home S5, pin 12

Stepper motor control is implemented using a second real-time task

that runs at 100 microseconds. This task writes the parallel port

output with bits set or cleared based on whether the a pulse should be

raised or lowered. This gives an effective period of 200 microseconds

for a full up-and-down pulse, or a 5 kilohertz frequency.

Discrete I/O Controller EMCIO

The discrete I/O controller (bottom right in Figure

2) is written in C++, using the NIST RCS Library. It

is based on a hierarchy of C++ controller classes derived from the NML_MODULE

base class, each communicating using NML.

Discrete I/O controllers are highly machine-specific, and are not

customizable in general using the INI file technique used to configure

the more generic motion controller.

A C language application programming interface (API) between the

discrete I/O controller and the external world is provided so that

specific hardware can be integrated into the EMC without modifying any

of the core control code. Programmers must implement these API

functions for each board.

Task Executor EMCTASK

The Task Executor (at the top in Figure

2) is coded similarly to the discrete I/O controller, using the

NML_MODULE base class and the RCS Library. It is less machine specific

than the discrete I/O controller, as it is responsible for

interpreting G and M code programs whose behavior does not vary

appreciably between machines.

External Programs

Indicated at the very top in Figure 2 is the fourth component of the

EMC software, the external programs such as the graphical user

interface (GUI) or flexible manufacturing system (FMS) which are used

to run the EMC. These communicate using NML, sending messages such as

power on, enter automatic mode, run a program, or power down. GUIs may

send manual commands initiated by the operator, for example jogging

machine axes in manual mode, or homing each axis.

Figure 2. EMC controller software architecture. At the coarsest level,

the EMC is a hierarchy of three controllers: the task level command

handler and program interpreter, the motion controller, and the

discrete I/O controller. The motion controller is detailed in Figure 1. The discrete I/O controller is implemented

as a hierarchy of controllers, in this case for spindle, coolant, and

auxiliary (e.g., estop, lube) subsystems. The task controller

coordinates the actions of the motion and discrete I/O

controllers. Their actions are programmed in conventional numerical

control "G and M code" programs, which are interpreted by the task

controller into NML messages and sent to either the motion or discrete

I/O controllers at the appropriate times.

Configuring the EMC

The EMC is configured with files that are read at startup and used to

override the compiled defaults. No real controller will likely use the

compiled defaults, so you will certainly need to edit at least some of

these files to reflect the specifics of your machine.

There are four files: emc.ini, emc.nml, tool.tbl, and

rs274ngc.var. The first, emc.ini, contains all the machine parameters such

as servo gains, scale factors, cycle times, units, etc. and will

certainly need to be edited. emc.nml

contains communication settings for shared memory and network ports

you may need to override on your system, although it is likely that

you can leave these settings alone. tool.tbl

contains the tool information such as which pocket contains which

tool, and the length and diameter for each tool. rs274ngc.var contains variables specific to the

RS-274-NGC dialect of NC code, notably for setting the persistent

numeric variables for the nine work coordinate systems. The specific

formats of each of these files is detailed in the following sections.

Machine Configuration file emc.ini

The machine configuration file emc.ini follows the Microsoft INI file

format, in which values are associated with keywords on single lines,

perhaps in sections denoted with square brackets, e.g.,

[SECTION]

; COMMENT

SYMBOL = VALUE

Everything from the first non-whitespace character after the = up to

the end of the line is passed as the value, so you can embed spaces in

string symbols if you want to.

You can edit the values for each keyword in any text editor. The

changes won't take effect until the next time the controller is

run. The file should be called emc.ini, but the name can be overriden

using a command line argument to the controllers. See the section

"Starting Up" for information on how to do

this. The following sections detail each section of the configuration

file, using sample values for the configuration lines.

[EMC] Section

The [EMC] section contains general parameters for the whole

controller. These are:

-

VERSION = $Revision: 1.14 $

The version number for the INI file. This is automatically updated

when using the Revision Control System, which looks for the $Revision: 1.14 $

string and appends the revision number. If you want to edit this

manually just change the number and leave the other tags alone.

-

MACHINE = My Controller

This is the name of the controller, which is printed out when it

runs. You can put whatever you want here.

[TASK] Section

The [TASK] section contains general parameters for EMCTASK, which includes primarily the NC language

interpreter and the sequencing logic for sending commands to EMCMOT and EMCIO.

-

CYCLE_TIME = 0.100

The period, in seconds, at which EMCTASK

will run. You can make this as small as you want to increase the

throughput. Making it 0.0 or a negative number will tell EMCTASK not to sleep at all. Ultimately the system

loading will limit the effective throughput.

[TRAJ] Section

The [TRAJ] section contains general parameters for the trajectory

planning module in EMCMOT.

-

AXES = 3

The number of controlled axes in the system.

-

LINEAR_UNITS = 0.03937007874016

The number of linear units per millimeter. For systems executing in

native English (inch) units, this value is as shown above. For systems

executing in native millimeter units, this value is 1. This does not

affect the ability to program in English or metric units in NC

code. It is used to determine how to interpret the numbers reported in

the controller status by external programs.

-

ANGULAR_UNITS = 1.0

The number of angular units per degree. For systems executing in

native degree units, this value is as shown above. For systems

executing in radians, this value is 0.01745329252167, or PI/180.

-

CYCLE_TIME = 0.010

The period in seconds at which trajectory calculations are

performed. This is a multiple of the period at which servo

calculations are performed, as set in the [AXIS_#] CYCLE_TIME entry. Trajectory

calculations are called at multiples of the servo period to plan

linear or circular motion in Cartesian space. These values are

interpolated at the servo period and run through the inverse

kinematics.

-

DEFAULT_VELOCITY = 1.0

The initial velocity used for axis or coordinated axis motion, in user

units per second.

-

DEFAULT_ACCELERATION = 100.0

The initial acceleration used for axis or coordinated acis motion, in

user units per second per second.

-

MAX_VELOCITY = 5.0

The maximum velocity for any axis or coordinated move, in user units

per second.

-

MAX_ACCELERATION = 100.0

The maximum acceleration for any axis or coordinated axis move, in

user units per second per second.

[AXIS_#] Sections

The [AXIS_0], [AXIS_1], etc. sections contains general parameters for

the individual axis control modules in EMCMOT. The axis section names begin numbering at

0, and run through the number of axes specified in the [TRAJ] AXES entry minus 1.

-

TYPE = LINEAR

The type of axes, either LINEAR or ANGULAR. Values for the position of

LINEAR axes are in the units (per millimeter) specified in the [AXIS_#] UNITS entry. Values for

the position of ANGULAR axes are in the units (per degree) specified in

the same entry.

-

UNITS = 0.03937007874016

Units per millimeter for a LINEAR axis, as defined in the [AXIS_#] TYPE section, or units per degree for

an ANGULAR axis as defined in the same section.

The following parameters P, I, D, FF0, FF1, FF2 are used by the servo

compensation algorithm to optimize performance while tracking

trajectory setpoints. See Tuning Servos

for information on setting up a servomotor system.

-

P = 50

The proportional gain for the axis servo. This value multiplies the

error between commanded and actual position in user units, resulting

in a contribution to the computed voltage for the motor amplifier. The

units on the P gain are volts per user unit.

-

I = 0

The integral gain for the axis servo. The value multiplies the

cumulative error between commanded and actual position in user units,

resulting in a contribution to the computed voltage for the motor

amplifier. The units on the I gain are volts per user unit-seconds.

-

D = 0

The derivative gain for the axis servo. The value multiplies the

difference between the current and previous errors, resulting in a

contribution to the computed voltage for the motor amplifier. The

units on the D gain are volts per user unit per second.

-

FF0 = 0

The 0-th order feedforward gain. This number is multiplied by the

commanded position, resulting in a contribution to the computed

voltage for the motor amplifier. The units on the FF0 gain are volts

per user unit.

-

FF1 = 0

The 1st order feedforward gain. This number is multiplied by the

change in commanded position per second, resulting in a contribution

to the computed voltage for the motor amplifier. The units on the FF1

gain are volts per user unit per second.

-

FF2 = 0

The 2nd order feedforward gain. This number is multiplied by the

change in commanded position per second per second, resulting in a

contribution to the computed voltage for the motor amplifier. The

units on the FF2 gain are volts per user unit per second per second.

-

CYCLE_TIME = 0.001

This is the period in seconds at which servo calculations will

run. The values can be different between different axes, and the

lowest will be used for all. This ensures that the calculations will

occur at least as fast as they are specified here. The value should be

an integer submultiple of the trajectory cycle time specified in the

[TRAJ] CYCLE_TIME entry, so that an

integer number of interpolations will occur. If this is not the case

the times will be forced so that the interpolation interval is the

next highest integer.

-

INPUT_SCALE = 40000 0

These two values are the scale and offset factors for the axis input

from the raw feedback device, e.g., an incremental encoder. The second

value (offset) is subtracted from raw input (e.g., encoder counts),

and divided by the first value (scale factor), before being used as

feedback. The units on the scale value are in raw units (e.g., counts)

per user units (e.g., inch). The units on the offset value are in raw

units (e.g., counts).

Specifically, when reading inputs, the EMC first reads the raw sensor values.

The units on these values are the sensor

units, typically A/D counts, or encoder ticks. These units, and the

location of their 0 value, will not in general correspond to the

quasi-SI units used in the EMC. Hence a scaling is done immediately upon

sampling:

input = (raw - offset) / scale

The value for scale can be obtained analytically by doing a unit

analysis, i.e., units are [sensor units]/[desired input SI units]. For

example, on a 2000 counts per rev encoder, and 10 revs/inch gearing,

and desired units of mm, we have

[scale units] = 2000 [counts/rev] * 10 [rev/inch] * 1/25.4 [inch/mm]

= 787.4 counts/mm

and, as a result,

input [mm] = (encoder [counts] - offset [counts]) / 787.4 [counts/mm]

Note that the units of the offset are in sensor units, e.g., counts,

and they are pre-subtracted from the sensor readings. The value for

this offset is obtained by finding the value of counts for which you

want your user units to read 0.0. This is normally accomplished

automatically during a homing procedure.

-

OUTPUT_SCALE = 1 0

These two values are the scale and offset factors for the axis output

to the motor amplifiers. The second value (offset) is subtracted from

the computed output (in volts), and divided by the first value (scale

factor), before being written to the D/A converters. The units on the

scale value are in true volts per DAC output volts. The units on the

offset value are in volts. These can be used to linearize a DAC.

Specifically, when writing outputs, the EMC first converts the desired

output in quasi-SI units to raw actuator values, e.g., volts for an

amplifier DAC. This scaling looks like:

raw = (output - offset) / scale

The value for scale can be obtained analytically by doing a unit

analysis, i.e., units are [output SI units]/[actuator units]. For

example, on a machine with a velocity mode amplifier such that 1 volt

results in 250 mm/sec velocity, we have:

[scale units] = 250 [mm/sec] / 1 [volts]

= 250 mm/sec/volt

and, as a result,

amplifier [volts] = (output [mm/sec] - offset [mm/sec]) / 250 [mm/sec/volt]

Note that the units of the offset are in user units, e.g., mm/sec, and

they are pre-subtracted from the sensor readings. The value for this

offset is obtained by finding the value of your output which yields

0.0 for the actuator output. If the DAC is linearized, this offset is

normally 0.0.

The scale and offset can be used to linearize the DACs as well,

resulting in values that reflect the combined effects of amplifier

gain, DAC non-linearity, DAC units, etc. To do this, follow this

procedure:

a. Build a calibration table for the output, driving the DACs with a

desired voltage and measuring the result, e.g.,

RAW MEAS

--- ----

-10 -9.93

-9 -8.83

0 -0.03

1 0.96

9 9.87

10 10.87

b. Do a least-squares linear fit to get coefficients a, b such that

meas = a * raw + b

c. Note that we want raw output such that our measured result is

identical to the commanded output. This means

cmd = a * raw + b

raw = (cmd - b) / a

As a result, the a and b coefficients from the linear fit can be used

as the scale and offset for the controller directly.

-

MIN_LIMIT = -1000

The minimum limit (soft limit) for axis motion, in user units. When

this limit is exceeded, the controller aborts axis motion.

-

MAX_LIMIT = 1000

The maximum limit (soft limit) for axis motion, in user units. When

this limit is exceeded, the controller aborts axis motion.

-

MIN_OUTPUT = -10

The minimum value for the output of the PID compensation that is

written to the motor amplifier, in volts. The computed output value is

clamped to this limit. The limit is applied before scaling to raw

output units.

-

MAX_OUTPUT = 10

The maximum value for the output of the PID compensation that is

written to the motor amplifier, in volts. The computed output value is

clamped to this limit. The limit is applied before scaling to raw

output units.

-

FERROR = 1.0

MIN_FERROR = 0.010

FERROR is the maximum allowable following error, in user units. If the

difference between commanded and sensed position exceeds this amount,

the controller disables servo calculations, sets all the outputs to

0.0, and disables the amplifiers. If MIN_FERROR is present in the .ini

file, velocity-proportional following errors are used. Here, the

maximum allowable following error is proportional to the speed, with

FERROR applying to the rapid rate set by [TRAJ] MAX_VELOCITY, and

proportionally smaller following errors for slower speeds. The maximum

allowable following error will always be greater than MIN_FERROR. This

prevents small following errors for stationary axes from inadvertently

aborting motion. Small following errors will always be present due to

vibration, etc.

The following polarity values determine how inputs are interpreted and

how outputs are applied. They can usually be set via trial-and-error

since there are only two possibilities. The EMCMOT utility program USRMOT can be used to set these

interactively and verify their results so that the proper values can

be put in the INI file with a minimum of trouble.

-

ENABLE_POLARITY = 0

The polarity for enabling the amplifiers. Set this to 0 or 1 for the

proper polarity. This value can be determined by following all the

electronics back from the amplifier, through any driver circuitry,

etc. or it can be set through a simple trial-and-error. Normally, for

amplifiers which are enabled active-low (0 volts enables), this is a

0.

-

MIN_LIMIT_SWITCH_POLARITY = 1

The polarity for detecting minimum-travel hardware limit switch

trips. Set this depending on how your switches are wired up to the

digital inputs on the I/O board.

-

MAX_LIMIT_SWITCH_POLARITY = 1

The polarity for detecting maximum-travel hardware limit switch

trips. Set this depending on how your switches are wired up to the

digital inputs on the I/O board.

-

HOME_SWITCH_POLARITY = 1

The polarity for detecting homing switch trips. Set this depending on

how your switches are wired up to the digital inputs on the I/O

board.

-

HOMING_POLARITY = 1

The direction in which homing moves are initiated. 0 means in the

negative direction, 1 means in the positive direction.

-

FAULT_POLARITY = 1

The polarity for detecting amplifier faults. Set this to 0 or 1

depending upon how the amplifier sets the logic level for its fault

condition.

The following entries are used to set the parameters for the

DC servomotor simulations. These are only used when running the EMC in

simulation.

-

TORQUE_UNITS = OZ_IN

The units used to interpret subsequent values for ROTOR_INERTIA and DAMPING_FRICTION_COEFFICIENT.

This can be OZ_IN for ounce-inches, LB_FT for pound-feet, or N_M for

newton-meters.

-

ARMATURE_RESISTANCE = 1.10

The resistance, in ohms, of the motor.

-

ARMATURE_INDUCTANCE = 0.0120

The inductance, in henries, of the motor.

-

BACK_EMF_CONSTANT = 0.0254

The back EMF constant, or torque constant, in volts per radian per

second.

-

ROTOR_INERTIA = 0.0104

The rotor inertia, in torque units *

seconds2.

-

DAMPING_FRICTION_COEFFICIENT = 0.083

The damping coefficient, in torque units

per radian per second.

-

SHAFT_OFFSET = 0

The angular offset, in radians, between the the motor initial position

and the encoder initial position. Normally this is 0, but can be made

any arbitrary value if the simulated motor shaft position is

interpreted as the actual axis position and should be something other

than 0 when the encoder reports 0.

-

REVS_PER_UNIT = 10

The amount of motor shaft revolutions per user unit of position. For

example, for a 1/10 inch lead screw, where 10 rotations equals 1 inch,

this would be 10.

The following entry is used to set the parameters for the

amplifier simulations. These are only used when running the EMC in

simulation.

-

AMPLIFIER_GAIN = 1

The gain of the amplifier, which multiplies the input voltage to

generate an output voltage which drives the motor.

-

MAX_OUTPUT_CURRENT = 10

The maximum output current of the amplifier, in amps.

-

LOAD_RESISTANCE = 1.10

The resistance, in ohms, of the load on the amplifier. This is

normally the same as the motor armature

resistance, but it may not be, for example, if there is additional

resistive load between the amplifier and the motor itself.

The following entry is used to set the parameters for the

encoder simulations. These are only used when running the EMC in

simulation.

-

COUNTS_PER_REV = 4096

The number of encoder counts per motor shaft revolution. If

there is gearing between the encoder shaft and the motor shaft, this

value should include this.

[EMCIO] Section

The [EMCIO] section contains control values and setup parameters for

the digital and analog I/O points in EMCIO.

The following entries set general parameters for the I/O controller.

-

CYCLE_TIME = 0.100

The period, in seconds, at which EMCIO

will run. You can make this as small as you want to increase the

throughput. Making it 0.0 or a negative number will tell EMCIO not to sleep at all. Ultimately the system

loading will limit the effective throughput.

-

TOOL_TABLE = tool.tbl

The file which contains tool information. The format of the file is

POC FMS LEN DIAM COMMENT

1 1 0 0

2 2 0 0

where the first line is a comment (in this case the name of the

columns), and the subsequent lines contain the pocket number in which

the tool is located, the tool ID of the tool itself, the length, the

diameter, and an optional comment. The length and diameter are in user

units.

The following entries set parameters for spindle control.

-

SPINDLE_OFF_WAIT = 1.0

How long, in seconds, to wait after the spindle has been turned off

before applying the brake.

-

SPINDLE_ON_WAIT = 1.5

How long, in seconds, to wait after the spindle brake has been

released before turning the spindle on.

The following entries set the bit indices for the digital I/O so that

the controller knows the mapping to I/O point wiring. The indices

start at 0 for the least significant bit in the digital I/O map. See

Setting up the External Interfaces

for information on interfacing I/O boards to the software.

-

ESTOP_SENSE_INDEX = 1

The location of the input bit which is used to detect whether the system is

in ESTOP.

-

LUBE_SENSE_INDEX = 2

The location of the input bit which is used to detect whether the

lubrication level is OK or low.

-

SPINDLE_FORWARD_INDEX = 1

The location of the output bit which is used to drive the spindle

forward. Only applicable to manual spindles.

-

SPINDLE_REVERSE_INDEX = 0

The location of the output bit which is used to drive the spindle in

reverse. Only applicable to manual spindles.

-

MIST_COOLANT_INDEX = 6

The location of the output bit which is used to turn mist coolant on

or off.

-

FLOOD_COOLANT_INDEX = 7

The location of the output bit which is used to turn flood coolant on

or off.

-

SPINDLE_DECREASE_INDEX = 8

The location of the output bit which is used to decrease the spindle

speed. Only applicable to manual spindles.

-

SPINDLE_INCREASE_INDEX = 9

The location of the output bit which is used to increase the spindle

speed. Only applicable to manual spindles.

-

ESTOP_WRITE_INDEX = 10

The location of the output bit which is used to cause an ESTOP.

-

SPINDLE_BRAKE_INDEX = 11

The location of the output bit which is used to engage or release the

spindle brake.

The following entries set the polarities for the digital I/O

points. These can be set by trial-and-error, or by noting the levels

and any inverting done by the electronics between the sensors and

actuators and the electronics.

Using the USRMOT Motion Utility

USRMOT is an interactive text-based utility

that is used to set and test motion parameters for the EMCMOT motion controller. To use USRMOT, first run EMCMOT

standalone (yourprompt> represents whatever your system prompt is):

yourprompt> emcmot

In another window, run the USRMOT utility:

yourprompt> usrmot

motion>

The motion> prompt is displayed by USRMOT

when it runs. Entering a blank line lets you see the status:

motion>

mode: free

cmd echo: 0

split: 0

heartbeat: 605

compute time: 0.014992

traj time: 0.200000

servo time: 0.020000

interp rate: 10

axes enabled: 0 0 0

cmd pos: 0.000000 0.000000 0.000000

act pos: 0.000000 0.000000 0.000000

velocity: 10.000000

accel: 100.000000

id: 0

depth: 0

active depth: 0

inpos: 1

vscales: Q: 1.00 X: 1.00 Y: 1.00 Z: 1.00

logging: closed and stopped, size 0, skipping 0, type 0

homing: ---

enabled: DISABLED

Tuning Servos

For a detailed description of tuning servos, see the following

references:

-

Benjamin C. Kuo, Automatic Control Systems, Fourth Edition.

Defining Complex Kinematics

By default the EMC assumes trivial Cartesian kinematics in which X, Y,

and Z coordinates map directly to motors 0, 1, and 2. You can define

more complex kinematics, for example for a robot, by replacing the

default kinematics functions with your own.

The C language declaration for the kinematics, found in emcmot.h, is

#include "posemath.h" /* PmPose */

extern int forwardKinematics(double * joints, PmPose * pos);

extern int inverseKinematics(PmPose pos, double * joints);

You can replace these with any kinematics you like, provided they

conform to these declarations. Replace the file trivkins.o from the link line that builds emcmot with your own, and rerun the compiler.

Setting up the External Interfaces

The interface between motion control and discrete I/O control points

and the software is declared in the C language header file extintf.h.

For example, one of the external APIs is

/*

extDacWrite(int dac, double volts)

writes the value to the DAC at indicated dac, 0 .. max DAC - 1.

Value is in volts. Returns 0 if OK, -1 if dac is out of range.

*/

extern int extDacWrite(int axis, double voltage);

which is called by the motion controller to output a voltage to the

motor velocity amplifiers. For a particular digital-to-analog

converter board, the function would be implemented as something like:

/* specific function to output voltage for my board */

int myBoardDacWrite(int axis, double voltage)

{

short int vout;

vout = (short int) (voltage / 10.0 * 0xFFFF);

_outw(0x280 + axis, vout);

return 0;

}

/* mapping of my function to API */

int extDacWrite(int axis, double voltage)

{

return myboardDacWrite(axis, voltage);

}

Another external API is

/* reads value of digital input at index, stores in value */

extern int extDioRead(int index, int *value);

which is called by the discrete I/O controller to read a digital input

into the 'value' variable, from the I/O point at the specified

'index'. For a particular digital I/O board, the function would be

implemented as something like:

/* specific function to input value from myboard */

int myBoardDioRead(int index, int *value)

{

unsigned char mask;

mask = 1 << index % 8;

*value = (_inb(0x380 + index / 8) & mask) ? 1 : 0;

return 0;

}

/* mapping of my function to API */

int extDioRead(int index, int *value)

{

return myboardDioRead(index, value);

}

The code above is referred to as a "wrapper" for myboard. NIST has

written wrappers for some specific boards. See Wrapped Hardware for more information.

Starting Up

The EMC can be started up by scripts, which take command line

arguments for the various files if their names are to be

overriden. The scripts should be run in the directory in which the

configuration file are located, unless they are overriden with paths

to alternate files. The conventional practice is to create a script

file called run.emc based on one of the

example run scripts, and run it in the top-level emc directory where

the configuration files emc.ini and emc.nml are located. The syntax is:

./run.sunos5

Control Platforms

From the point of view of technology transfer, the EMC has strived to

provide software which is of high performance yet can be run on

inexpensive computing platforms. The target platform for control is a

PC-compatible desktop computer, 386-compatible or higher, with a

minimum of additional hardware. We have ported our software to the

Linux operating system, since it is free and has free real-time

support from New Mexico Tech. We also run in simulation on most

Unixes, and Microsoft Windows NT. The following are some links to

related Web sites.

|

No approval or endorsement of any commercial product by the National

Institute of Standards and Technology is intended or implied. Certain

commercial equipment, instruments, or materials are identified in this

report in order to facilitate understanding. Such identification does

not imply recommendation or endorsement by the National Institute of

Standards and Technology, nor does it imply that the materials or

equipment identified are necessarily the best available for the

purpose.

|

PC Hardware

These links provide information on PC-compatible hardware in

general. Go here for technical specs, pinouts, I/O addresses and

register bitmaps, etc.

Linux Documentation

There is a world of free information on Linux, the free Unix-like

operating system for 'most any platform. You can get it for PCs,

Macintoshes, Sparc workstations, notebook computers, and more.

Linux Software

Third parties provide shrink-wrapped Linux packages which save you the

trouble of ftp-ing 20 megabytes of code from Finland over your 28.8

kbps modem overnight. You can also find lots of free software for

Linux.

- Linux Distributions

Commercial versions of Linux, with manuals, graphical installation and

configuration tools, etc. on a CD.

Real-time Linux

Michael Barabanov and Victor Yodaiken of New Mexico Tech modified the

Linux source slightly, inserting a real-time scheduler between Linux

and the hardware interrupts it used to receive. Now, your code can run

in the scheduler, with Linux running when you're done. Tasks can run

at cycle times down to about 50 microseconds or so. That's 20

kilohertz in real-time on your desktop PC.

- Real-time Linux

New Mexico Tech's Linux tour de force, giving Linux real-time

determinism. RT-Linux is not a real-time operating system, but a

real-time subsystem, in which code that requires limited

operating system resources can run without being bothered.

Programming Linux

Information on accessing hardware or operating system resources not

covered in general C language textbooks.

- IO

Port Programming

Here's something on programming Intel X86 I/O ports in Linux, via the

usual inb() and outb() functions.

- Using Shared Memory in RT-Linux

Linux and RT-Linux processes communicate between themselves using FIFOs,

but shared memory has some advantages. Here's information on how to

set it up and use it.

Wrapped Hardware

We have written APIs to some hardware for our installations, giving

them the functional interface we program to in our

EMC code. Here

are some of them.

- External Interface API

The C language header file for API used by the EMC software when

reading and writing to I/O boards for A/D, D/A, digital I/O, encoders,

et cetera. Implementations of these functions need to be written by

EMC integrators. In the body of these functions should be calls to the

specific boards used in the implementation.

extintf.h

- Servo To Go, Inc.

Servo To Go 4- and 8-axis electronic interface card, with D/A

converters, encoder quadrature counters, digital I/O, optional analog

input. EMC supports the Model 1 board. We don't yet have a driver for

the Model 2 board. If you're going to use this board, here are the pin

assignments.

stg.h

stg.c

extstgmot.c

- Parallel Port for Digital I/O

The PC parallel port can be used for 12 general-purpose digital

outputs and 5 digital inputs.

parport.h

parport.c

extppt.c

|